1. Audio Mastering for Vinyl

Vinyl-specific mastering is critical. Engineers adjust bass levels, stereo width, and high frequencies to ensure smooth playback and prevent groove distortion.

2. Lacquer Cutting

The mastered audio is engraved onto a lacquer disc using a precision lathe. This step demands extreme accuracy—any flaw here will be replicated in every copy.

3. Electroplating and Stamper Creation

The lacquer is coated in metal to create stampers. High-quality plants use multi-stage electroforming to maintain groove accuracy and durability.

4. Vinyl Pellet Selection

Premium plants use virgin vinyl pellets rather than recycled material. This results in:

- Cleaner sound

- Fewer pops and clicks

- Greater longevity

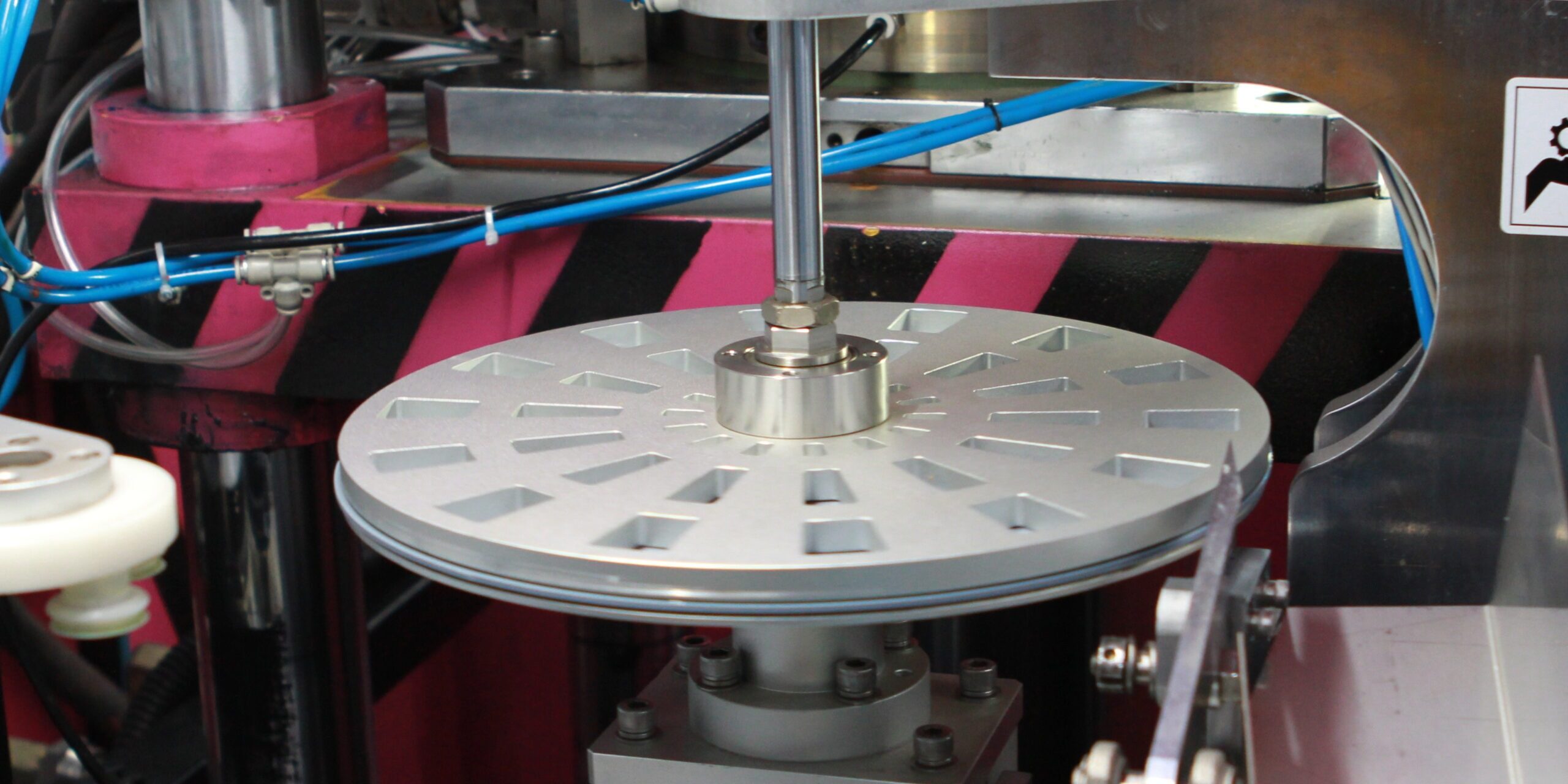

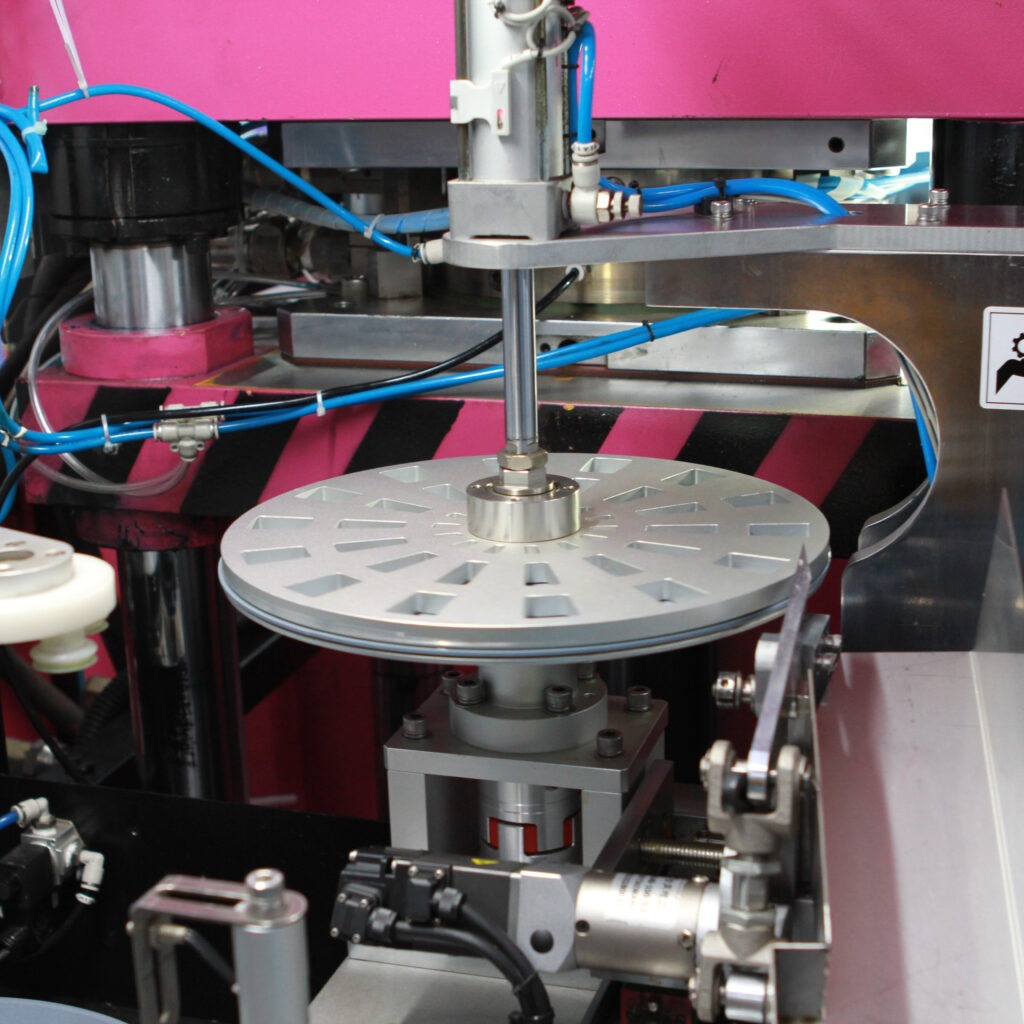

5. Hydraulic Pressing

Stampers press heated vinyl into shape. Plants focused on quality maintain strict temperature, pressure, and timing controls.

6. Cooling and Trimming

Proper cooling prevents warping. Automated trimming ensures uniform edges and weight consistency.

7. Visual and Audio Quality Control

Each batch undergoes test pressings, visual inspection, and playback testing to ensure flawless output.

Key Features of a Vinyl Record Pressing Plant with High Quality

| Feature | Why It Matters |

|---|---|

| Virgin Vinyl Material | Cleaner sound and durability |

| Precision Pressing Machines | Consistent groove depth |

| Experienced Engineers | Fewer defects |

| Strict QC Standards | Reliable final product |

| Climate-Controlled Facilities | Prevents warping |

Purple Media – A Vinyl record pressing plant with high quality equipment preserves the emotional depth of music while meeting modern listener expectations.